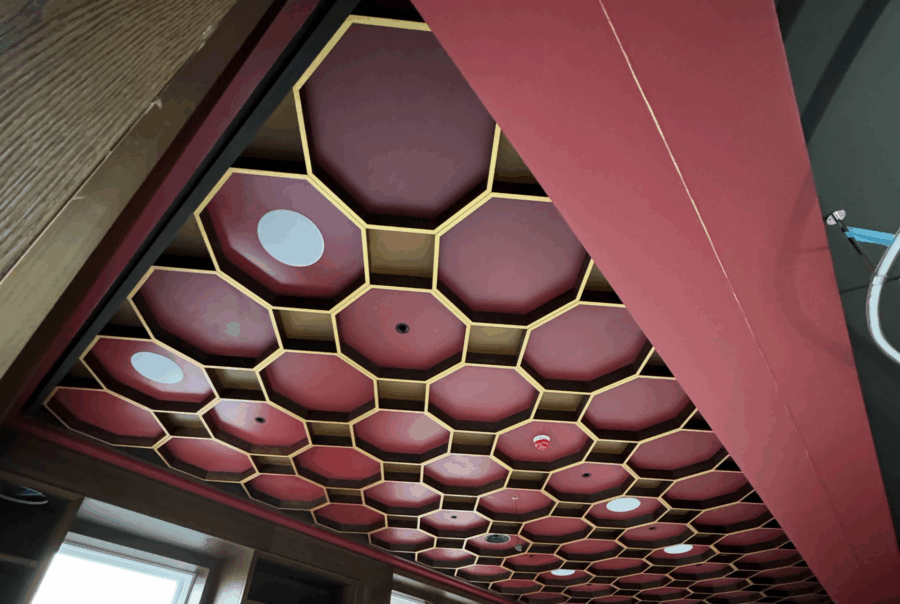

Bespoke joinery often sits at the intersection of design ambition and technical execution. One recent example is the honeycomb-shaped ceiling created by Vascroft’s in-house joinery team – a feature that combines strong visual impact with meticulous craftsmanship and technical foresight.

We spoke to Jayesh Patel, a long-standing member of the Vascroft team, to understand how this complex ceiling came together, from early concept through to installation on site in a Grade II-listed redevelopment adjacent to Hyde Park Corner in central London.

The Original Brief: Design First, But Not Design Alone

The project began with intent drawings from the designer, where the visual outcome was a clear priority. As Jayesh explains, “The look was key,” but as is often the case with ceiling work, there are many considerations beyond aesthetics – “like how the light will fit, how can we get access if something goes wrong.”

This early-stage thinking is critical. As Jayesh notes, “Once the background work is done, it becomes very easy going forward.” As a result, the team places strong emphasis on gathering as much information as possible upfront, asking the right questions early to avoid challenges later down the road.

Once these functional and technical considerations are fully resolved and all information is in place, Vascroft ensures the client remains informed and confident throughout the process. As Jayesh explains, “We always make a sample for approval first and we get the client to sign off.”

Materials & Techniques: Geometry Demands Precision

The ceiling’s striking honeycomb pattern required both material stability and high-precision manufacturing.

“The main material was oak veneer,” says Jayesh. “We had to press the veneer to MDF then cut each corner to get the octagon shape.”

Each individual piece was mitred using a panel saw – an exacting process that ensured consistency across the entire ceiling. With this kind of repeating geometry, accuracy is critical, as every single piece must align perfectly.

Quality Control: Getting It Right Before It Leaves the Workshop

Quality assurance was embedded throughout the process. As Jayesh explains, “We have quality checks in every department,” and before anything leaves the workshop, “I ensure the quality is correct and nicely packed.”

This layered approach to quality control ensures that what arrives on site is fully prepared for a smooth and accurate installation.

The Biggest Challenge: Installation on Site

Manufacturing took place in a controlled environment within Vascroft’s joinery workshop, which made that phase relatively straightforward – or as Jayesh puts it, “Easy part is to manufacture as we have open space.”

Installation, however, proved to be the most technically demanding stage. “To fit them on site it was a different ball game, we had to use hanging rods to hang them to the ceiling, whilst making sure each corner matched.” In addition, “because it is a ceiling fixture, we had to spray finish this with flame retardant lacquer – a building control requirement.”

With multiple layers of complexity, from aesthetics and safety compliance to installation precision, perfection was essential. To ensure a smooth installation, the team produced four full samples in advance so that “Everyone knew how this was getting installed – once that exercise was done, the rest became very easy.” From that point on, the site team executed the installation exactly as planned.

A Career Built on Craftsmanship, Trust and Passion

For Jayesh, the project reflects what he enjoys most about joinery, and about working at Vascroft. “I’ve been working with Vascroft over 20 years, and every day I learn something new. You never get bored with this job. I treat this as if it is mine, so I enjoy every single minute with this company.”

He credits the success of the work to the strength of the team around him. “My team are very skilled, high-quality carpenters – without them it would be very difficult. It’s all about trust: if you trust them, they trust you.”

Supporting the Next Generation

That same sense of trust extends to developing new talent within the team. As Jayesh shares, “We’ve had a young chap join us recently – Shawn – and he’s gelled with the team really nicely.” The team remains committed to the future of the trade, being “very open to nurturing the next generation who are willing to learn and show their skills.”